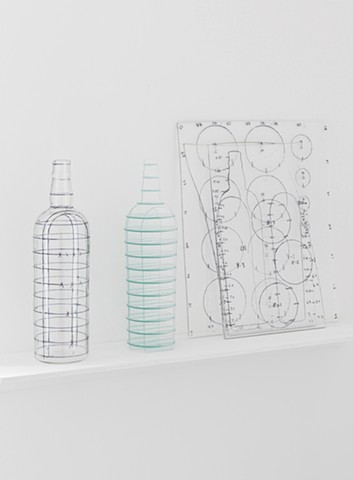

Anatomy of a Waffle Bottle

In the summer of 2015, I was given access to a water-jet mill and a technician with extensive experience and exceptional dexterity with this piece of equipment. In my own glass making practice, I have spent years practicing a specific blown bottle shape in an attempt to become a better glassblower, but also with a conceptual goal of addressing the space between the handmade and machine made. This larger project points to ideas about alienation of craft practices from daily life as a result of the Industrial Revolution. Taking the aforementioned hand-blown, but referencing machine blown bottle, I mapped the contours of the object and drew a precise rendering in a 3D modeling program. That form was then spliced into vertical and horizontal planes that can be reassembled with a slot system. This object architecture is colloquially understood within the 3D modeling field as a “waffle”.

To take this process one step further in order to address my core concern of the space between the hand made and the machine made, I blew several glass cylinders, which were then cut and slumped open into a sheet. This process is a traditional and anachronistic process for making flat glass for windows. Once generated, the sheet glass replaced the industrially precise float glass typically used on the water-jet mill. In order for the slot system of the waffle to work, each slot had to be mapped according to where in the variably thick sheet of glass it would be cut so that the corresponding slot could be adjusted within the water-jet’s software. Essentially making a process designed for efficiency and ease, exponentially more labor intensive and time consuming. I am more often than not alienated from new, technology based, processes because I am inclined to relish in and find important creative choices within the minutia of the process. This project seeks compatibility with technology by insinuating human labor into areas normally left to standardization and automation.